Fasteners Tutorial : 8 Steps - smithweriatere

Insertion: Fasteners Tutorial

In this object lesson we will be discussing fasteners which attach pieces of metal together using automatic fond regard. What this means is that two (or more objects) are affixed jointly by a mechanical means.

There are a turn of common methods of fastening pieces of metal together, but thither are are a few which are most commonly encountered such as rivets, canvass metal screws, and nuts and bolts. In this run over we will be focusing primarily on nuts and bolts. The nice thing about this method acting is that it is very effectual, and can typically be easily undone.

This class will not be discussing other forms of adhesion including welding, brazing, bonding, or gluing. For more data almost these subjects, chink out the Welding, Jewelry, and the Glue classes.

Tread 1: Nuts and Bolts

Nuts and bolts are typically two pieces of hardened steel with threading upon them. A bolt is a threaded shaft with large mind that can be grabbed with a tool. A nut is a piece of metal with a threaded jam. The nut simply twists onto the bolt to form a strong bond. At that place are more types of nuts and bolts that you put up e'er imagine. Bolts can vary in the type of threading they have, the form of their head, the materials they are ready-made out of, and the personal manner of tool wont to catch up it. Nuts can vary by virtually as many a criteria As well.

Step 2: Threading

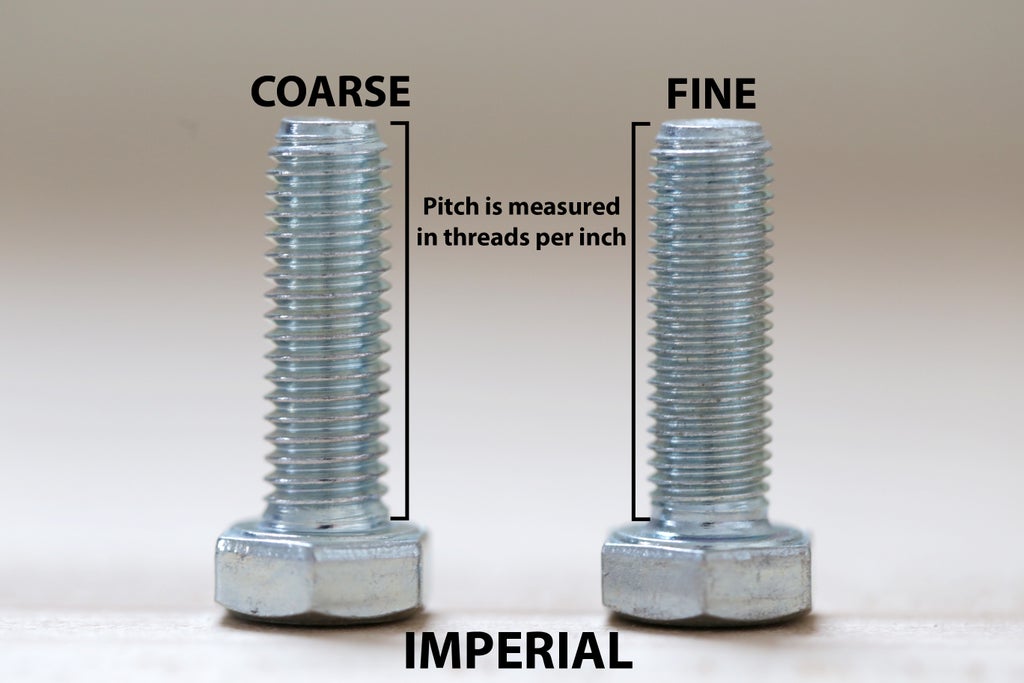

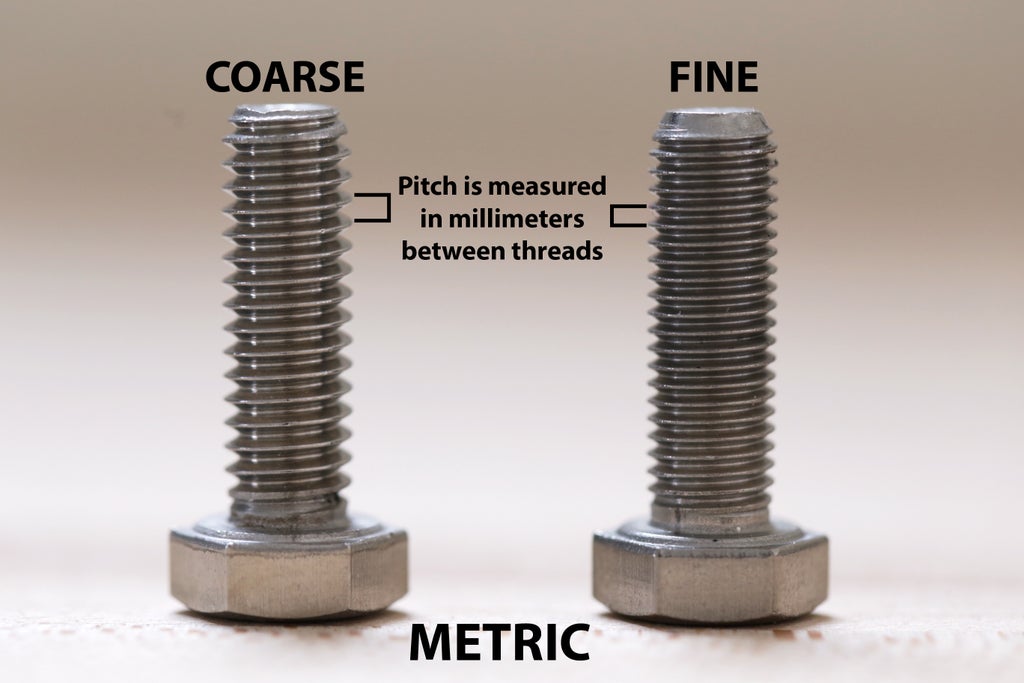

When approaching run off threading, thither are deuce aspects that you need to pay attention to, and those are the pitch and diameter. The pitch is the distance between the peaks of togs. The diameter is the width of the bolt's shaft.

In the United States, the diameter can either be metrical in imperial or metric. In most the rest of the world, you will likely be transaction exclusively in metric.

To further blur matters, the pitch is then measured otherwise depending along the type of bolt you are using.

Imperial bolts bar pitch in threads per inch. For instance, say you have a 1/4-20 bolt. This means that IT is 1/4" wide and has 20 duds per inch. If you want a finer threading, you may consider getting a 1/4-32 bolt, it is still 1/4" wide, only now has 32 threads per inch.

The more threads IT has per edge in, the finer the threading is considered. Conversely, bolts with less duds are considered "coarse." Regardless of threading, you will always need a nut with an identical pitch to match information technology.

Since the metric system does not use inches, rhythmic bolt threading is obviously not metrical in threads per edge. Instead, information technology is measured purely in millimeters. So, if you wealthy person an M6 x 1, IT means that the bolt is 6mm wide and the threads have a pitch that is 1mm apart (i.e. 1mm peak to peak). This is diametric purple in that as the pitch gets higher, the thread coarseness increases. The smaller the number, the greater the pitch. For instance, an M6 x 1 would be a practically finer pitch than an M6 x 1.5.

Step 3: Tapping

To tap a fix is to use a tap to cut a spiraling rut or "thread" into it. The purpose of tapping a hole is to make it so that a gobble up can be threaded into it. Thus, a abroach gob needs to exactly match the threading of the bolt. Like most concepts in metalworking, tapping a hollow can take a few minutes to "get," and a lifetime to master.

Taps have cutting blades which cut the threads Eastern Samoa they are twisted into the hole. The cut material ends up in the flutes cut into the pull. Unlike with drill bits which have helical (spiral) flutes, taps have straight flutes.

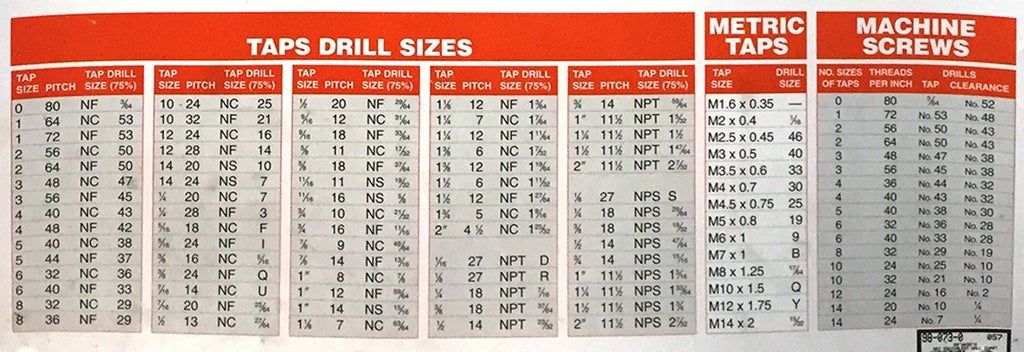

They make lights-out that match every imaginable bolt size and threading for both imperial and metric bolts. You can always find a spigot to meet your needs.

Whatever mess made in metal can be threaded if drilled to the proper size for a beg. This hole is always slightly smaller than the diameter of the bolt that gets threaded into it. To figure out what size hole needs to be trained, you should acknowledgment a tap chart. You can easily find one online, but if you really stupefy into this, you should print out or purchase one to hang happening your wall.

Step 4: Hardening Screws

In this lesson we leave be tapping the tercet holes we previously drilled to insert "set screws" into them. Despite the "screw" in their name, put away screws are actually specialized bolts which use tension to halt two objects together. Typically this involves pushing an entrapped part against the palisade of the other part which is entrapping it. In our case, we are going to use them to hold the spherical quartz glass lens to the inside of the tube. As the bolts buzz off tightened, they wish equal "grabbing" the sphere and retention IT in place. If this doesn't make gumption instantly, don't worry. It will make perfectible sense in a few lessons when we assemble it.

Step 5: Setup the Tap Handle

The tap handle has a square jaw, which conveniently clamps onto the angular shank at the end of the tap.

Firmly clinch the 6-32 tap into the tap address.

Step 6: Employ Tapping Fluid

Commit a fewer drop of tapping unstable into the yap you volition comprise tapping. This makes it much easier for the hydrant to cut grooves into the metal aside decreasing friction and reducing heat. If you don't believe me, try tapping one of the holes without tapping fluid (although, I do not recommend it).

It likewise frequently helps to circularise tapping runny onto the tap itself using a brush, even though it is likely not necessary for such spare metallic-looking stock.

Step 7: Thread the Pickle

We are going to tap totally ternary of the holes we antecedently drilled.

Tapping a gob is extremely simple in concept, only exceptionally difficult in practice. With each play:

- Turn clockwise one half-turn past where you stopped the last time

- Layover, back out 3-living quarters of the way counterclockwise

- Repeat

Fundamentally, you are cutting one half bi deeper at a time, and then patronage off to clear knocked out the chopped metal flakes. Since we are tapping clear through our piece of metal, proceed doing this until the tap is the whole way direct the hole and you encounter no longer resistance.

This sounds easy plenty, but is really difficult. It is important to fling slowly and stop when you begin to feel 'too much' resistance. Unfortunately, knowing how overmuch is too overmuch electric resistance is the type of thing that can only be conditioned through and through praxis finished time. You may even break a few taps. That's okay. We have all been there.

Break a tap is one of the most frustrating things you may encounter. If you are lucky, you may be able to recover by grabbing part of it with vise grips and carefully backing it out. However, 95% of the metre, the tap is now in there permanently and the hole is ruined. If the hole is critical to a larger assembly (and can't exist resettled elsewhere), then the entire section is ruined. Thence, it is important to fetch beneficial at tapping things properly, or you may feel a lot of act ending rising in the trash.

Step 8: Insert the Screws

Once you have tapped all three holes, trial to make sure the threading is proficient by inserting the set screws.

The first time you do this it may be a little stiff, and you may notice is cleans out some extra cutting off fluent and aluminum flakes from the jam. This is natural.

You are straight off ready to go on to the Polishing Aluminum lesson to give your subway a nice shine.

Did you find this useful, play, or fun?

Keep up @madeineuphoria to see my a la mode projects.

Be the First to Part

Recommendations

-

Anything Goes Repugn 2022

Source: https://www.instructables.com/Fasteners-Tutorial/

Posted by: smithweriatere.blogspot.com

0 Response to "Fasteners Tutorial : 8 Steps - smithweriatere"

Post a Comment